Svord – forged out of necessity.

A while ago, as I started getting back into the outdoors I decided I wanted to get a good bush knife. Always on the lookout for New Zealand Craftsman, I soon came across Bryan Baker and the Svord range of blades.

Brian got into making knives in 1983. Over 30 years ago he started making blades in a shed out the back of his parent’s farm. Now, though still on that farm, his business has grown significantly in size.

In the modern age of mass production, it’s nice to hold something that had been handcrafted and hand finished by someone who knows his craft inside out.

Talking to Bryan I (spontaneously) decided I would also like one of his Goloks (to be reviewed separately). He came back to me and said that he could make me a matching pair. The handles were made out of African Wenge Wood. I jumped at the offer and a short time later headed out to the shop to pick them up.

I also picked up a couple of his Peasant knives at the same time – again – another review shortly!

High Carbon vs. Stainless Steel

Knife steel is one of the subjects like Fords vs. Holdens – the owners are going to defend whatever it is they have to the bitter end. Also, simplifying it down to High Carbon vs. Stainless Steel can be very misleading – there are different grades within those names, different tempering methods and different knife profiles that all lead to variations on how hard things are to sharpen, how long they keep that edge and how easy it is to dull them again. All that’s before we start talking about laminates!

Go online and you will find people telling you the High Carbon or Stainless is harder and a pile of conflicting information. I have found High Carbon to be easier to sharpen, though once Stainless is sharp, it can stay sharper longer. Regardless, if you are carrying a decent knife into the bush, you should also at a minimum be carrying a small stone or steel rod to keep the blade sharp after extended use.

Bryan uses Carbon Steel for the simple fact that he believes it to be the best. As he would point out, the traditional Samurai Sword, Woodworking Tools, Sashimi Knives, all use Carbon Steel. It gives the best edge and is easiest to sharpen.

He also adds Nickel in order to give the knife a high impact resistance. This is why the knives may turn a little blue if washed under hot water.

The Rockwell C scale is the method used for determining hardness. The test involves forcing a diamond-tipped rod into a blade and recording the resistance met. Plain high-carbon knives are usually Rockwell C51 to C53; stainless-steel knives are often C56 to C58 and sometimes higher. As noted, this is only part of the equation though – as it doesn’t describe things like brittleness, toughness or resiliency.

Carbon Steel & Patina

Bryan uses a High Carbon Steel on all of his blades. One thing that Carbon Steel is going to do is Patina.

Patina is the covering that can happen on metals, it’s what makes Copper turn green. This happens as the surface of the metal oxidises; normally as a result of exposure to air and moisture. In the case of carbon steel, this patina is black staining that appears on the surface. It’s a form of surface rust – but one that actually works to protect the metal from further rusting once in place.

If you want a highly polished, clean looking knife, then carbon steel isn’t for you. You can clean them up, but really half the fun of these knives is letting them develop a unique signature patina. In fact, the patina can even speed up by applying a variety of products (orange juice, tomato sauce, a potato) to the knife directly.

The picture above is my 370B – the patina is the result of a night during a survival exercise where we had to build a debris shelter. That patina was caused by Punga juice! The blade isn’t damaged – it’s still razor sharp (people like to cut paper – so that is also my cut paper photo).

Left-handed. Sheaths.

While the Svord 370B does come with a nice leather sheath, I am left-handed, so it made it a little useless for me.

I decided to make myself up a Kydex Sheath. Imported the required materials in, spend a couple of hours making it up and done! Hip-mounted ‘Ranger Style’ sheath. I just mounted it using a couple of quick release Molle Straps and was away.

The Blade

The Svord 370BB is a full tang drop point 124mm blade. Overall the knife is just under 250mm long. Brass rivets and guard with an African Hardwood (custom) Handle. I have added the paracord lanyard (blaze is good in the bush). 178 grams in weight.

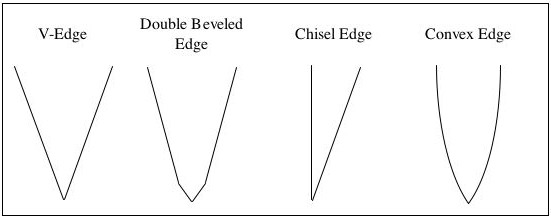

Bryan hand sharpens his deluxe blades into a convex edge. This essentially means the blade edge (and bevel) is rounded to the point.

It is said (and again, everyone has their own opinion) that the convex blade creates a stronger and longer lasting blade. It also means you need to be a little more careful sharpening them, but Bryan delivers them honed to a razor’s edge, so you normally only need to strop them to keep them sharp. Read up on sharpening with sandpaper and a mousepad if you want a pile more info on one way of converting a bevelled edge to convex.

Performance – can it dice?

All of this is fairly irrelevant if the thing can’t cut. However, cutting certainly isn’t an issue for the 370BB. Brain’s edge is razor-like. I don’t know if there is a standard set of cuts you are meant to do for a review – but I thought I would wander out into the bush and get a couple of nice shots and cut some things up at the same time.

You really shouldn’t be using your knife as an axe. Because that’s what an axe is for. However, if you need to, the Svord 370B can certainly be used to hack away at a tree or a branch. It could take a long time, but the knife will do it. Size-wise, this isn’t the same as a Golok or Gurkha knife – so it’s not really designed for the job. But it will happily do it.

Feathersticks? Sure. Don’t really know why you would ever need to make one in the NZ bush – there is generally plenty of small tinder available anyhow – but yes, it will do it.

Batoning? Yeah. Guess so. Again. We are in NZ, look around, plenty of smaller wood to burn. But if you really want to take to the back of your knife with a hammer go ahead. It’s spine maybe not as wide as it could be for the task – but then, carry an axe if that’s really what you are into.

Gravy-beef Cutting

Oh yeah, now we are into the fun stuff.

We recently got adopted by a cat. Second time it’s happened.

Instead of feeding it dry biscuits and mystery meats, I decided to get hold of some gravy-beef and do what my parent’s used to do – cut up and feed the cat meat.

As an added benefit – it’s a great chance to try different knives for cutting, skinning and de-silvering meat.

The Svord 370BB handles the job well – especially the cutting. Remember – this is the same knife I have just bashed around in the bush – and it cut through the meat with no issues.

It was a little bit big in the hand for the job – compared to the smaller Wusthof knife I have, but certainly would be up to the task of skinning out an animal. I generally carry a smaller pocket-knife on me anyhow – so the combination would cover most things.

Halfway through cutting up the Beef I thought I would give it a quick strop – a couple of runs on a denim strop with some green compound on it – back to razor blade sharpness! It’s an easy knife to keep sharp – provided you give it a bit of regular TLC.

So, In Summary

Is the Svord 370BB The ultimate bush knife? I don’t know. Haven’t tried them all. Feel free to send me yours to compare. However, it does set a very high standard.

Beautiful looks, razor edge, patina’s in the most wonderful way. This, paired with a smaller pocket knife is going to cover 95% of all tasks you might need in the bush. Take a saw to cut through some bones and you are complete. It’s a knife I have now had for a few years, and it’s one that will be handed on as well.